New Mimaki Textile Printer Keeps Heriot Watt University At Cutting Edge

With a reputation for innovative education, enterprise and leading-edge applied research; Heriot Watt University’s School of Textiles and Design is one of the UK’s foremost teaching establishments and its recent investment in additional Mimaki textile printers puts its Textile Design and Fashion undergraduate courses at the cutting edge.

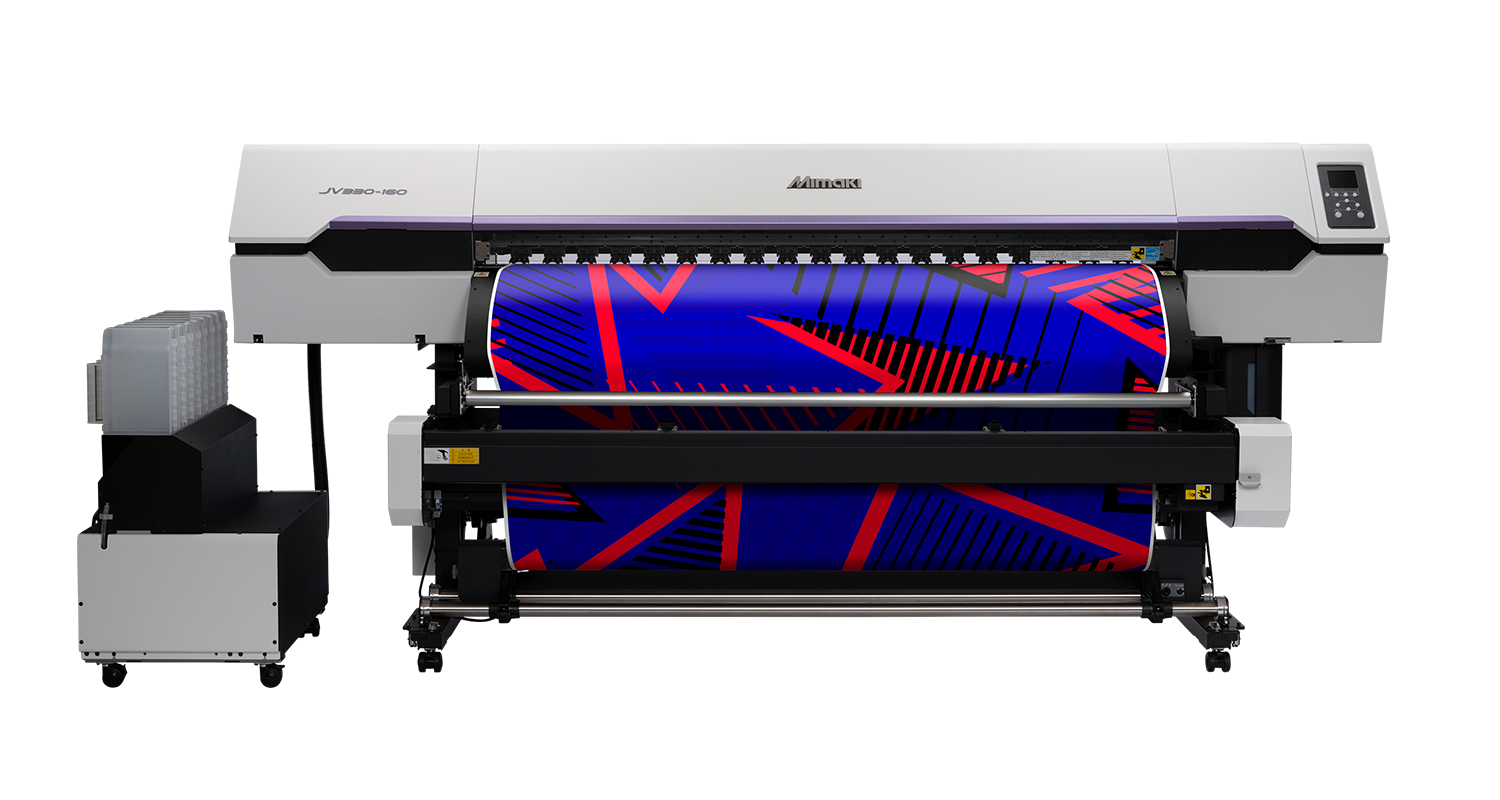

One of the first Mimaki TX300P-1800 Textile Printer direct-to-textile wide format printers to be installed in the UK joins the School’s line-up of Mimaki textile machines and provides its 25 final year Design for Textiles students with the capability to output designs onto a range of fabrics for their Degree Show. Senior Technician, Dr Roger Spark, indicates how the printer is a vital addition to the School’s print capabilities. “Our existing Mimaki printers have served us well for over 10 years but with the added capacity of the new Tx300, we’re able to more efficiently deliver the long runs required by our students for their final year collections,” he states. “We offer the potential for not only the Design for Textiles undergraduates to print their work but also the provision of printed fabric for our Fashion students to make into garments in our sewing workshops.”

Citing Heriot Watt’s emphasis on preparing graduates for life in industry, Spark details how effective the courses the School offers are. “Our graduates tend to follow one of two paths,” he says. “Many of them are successful in finding positions in the textile industry but we also see students starting up their own fashion and design businesses, as the footing they gain through the courses we offer stands them in good stead for their careers ahead.”

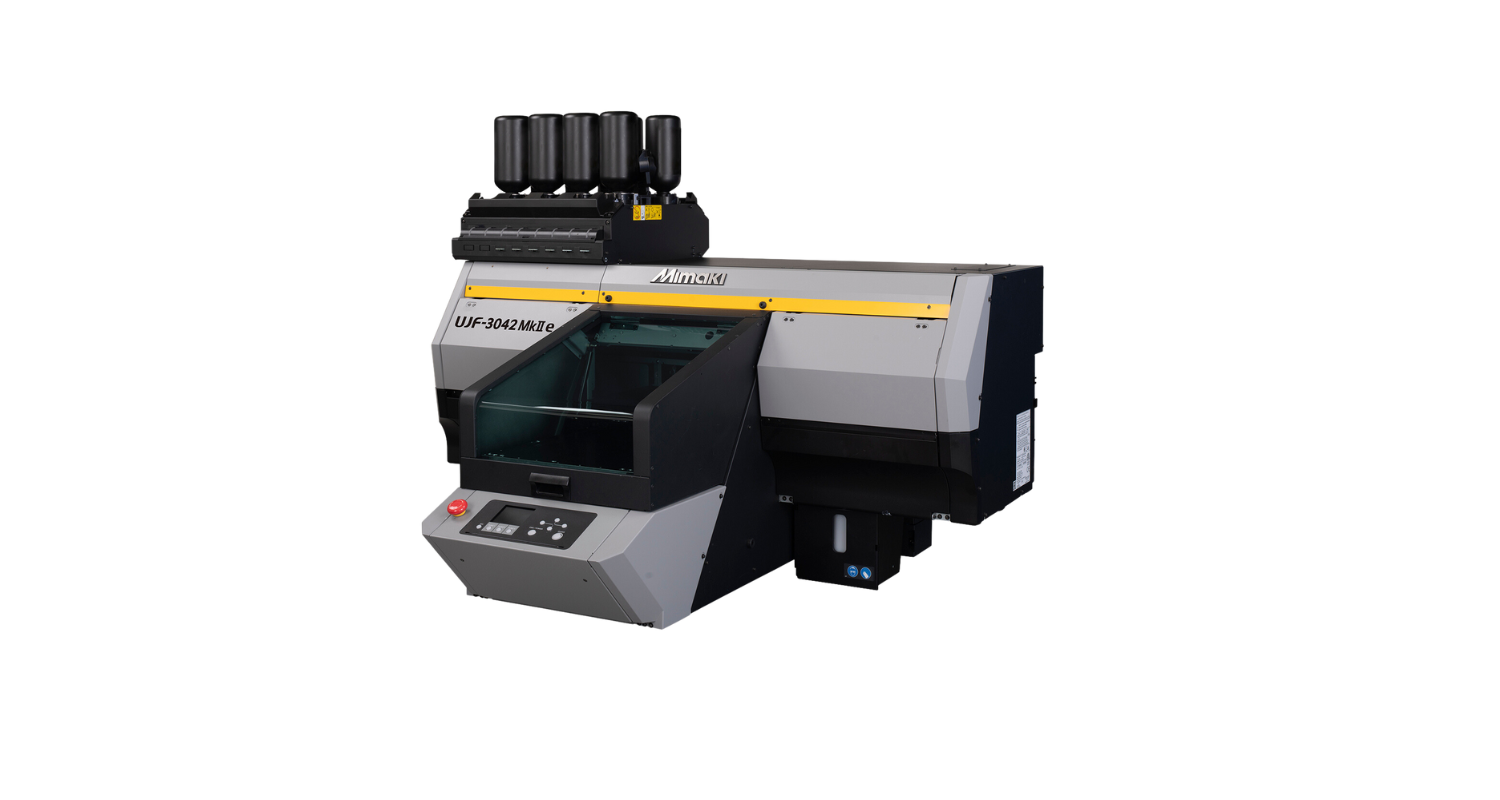

With programmes geared towards fashion as well as interior design, students benefit from the School’s significant printing capabilities. Along with its three Mimaki printers, the textile department also boasts one of the longest flatbed screen print tables in education and all were installed by specialist Mimaki textile reseller, R A Smart (CAD & Machinery).

“We’re proud of the enduring relationship we share with Heriot Watt,” says the company’s Managing Director, Magnus Mighall. “Their recent investment in the latest Mimaki textile printer will be of great benefit to the School and its students. Having supplied and supported the university with screen and digital print equipment for over 25 years; seeing their continued drive to deliver industry-ready graduates into the textile and fashion sector remains as satisfying as ever.”

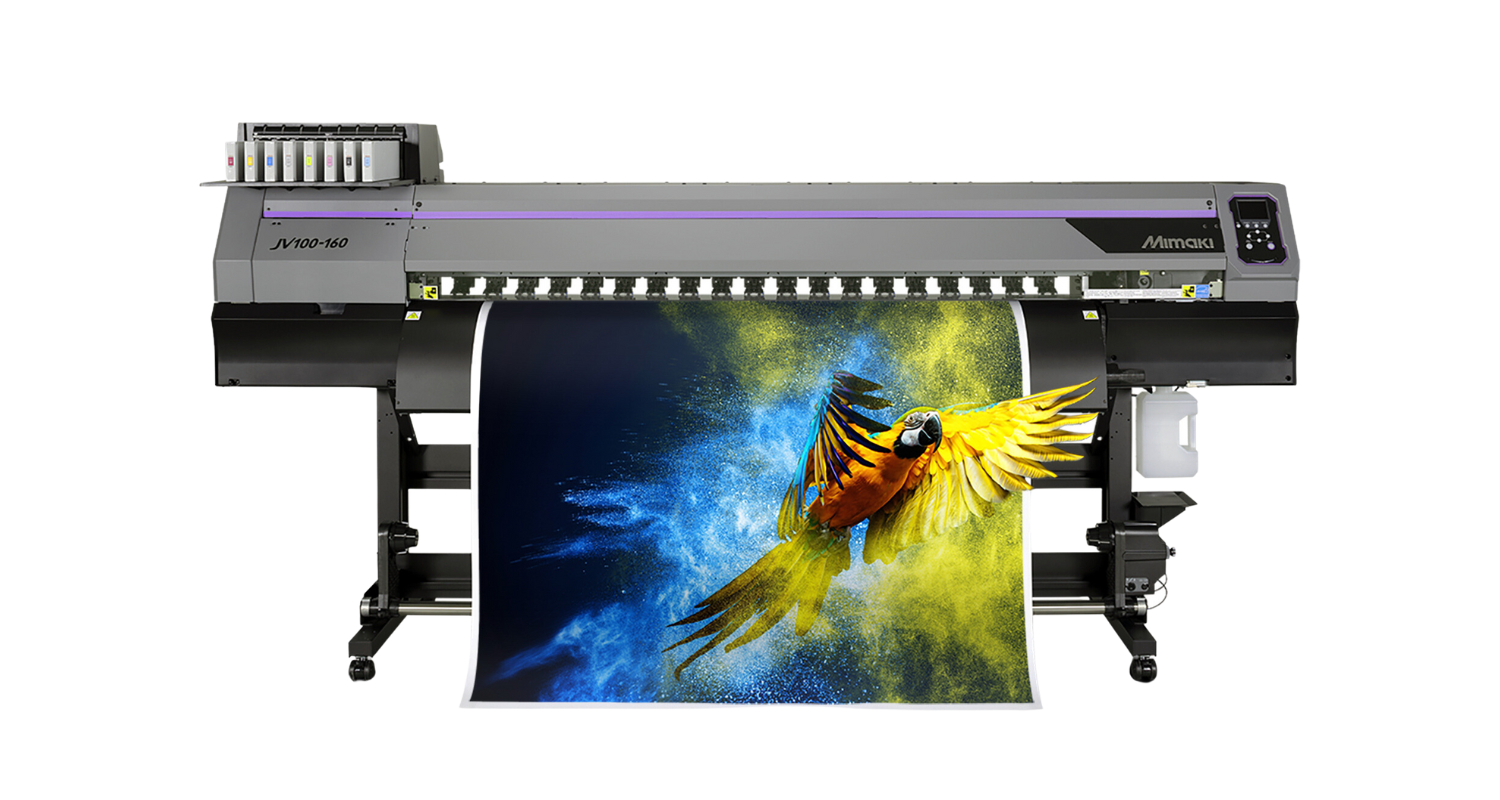

The Mimaki Tx300P-1800 is a 1.8m wide textile printer, which, through using reactive, pigment, acid or disperse inks, can be used to print to cotton, silk, wool and polyester. With production speeds of up to 55sq metres / hour, it is ideal for short to medium run production and its superior print quality lends it perfectly to producing high end fashion, furnishings and other textiles. Exclusively distributed in the UK and Ireland by Hybrid Services; the company’s National Sales Manager, Textile & Apparel – Stephen Woodall is excited about the impact the new Tx300P-1800 is already having. “This is one of the very first of the new printers to be installed in a university and it’s great to see students benefiting from the absolute latest textile printing technology,” he says. “Heriot Watt’s undergraduate textile courses offer a unique and valuable opportunity for prospective fashion designers to experience industry standard equipment and processes.”

With a critical element in textile printing being accurate colour management; Spark is seeing a tangible benefit in Mimaki’s latest reactive inks and profiles. “The School invested in a suite of Apple Macs running AVA design and colouring software a few years ago, and using these in conjunction with the colour profiles provided with the new Mimaki RIP package is delivering superb results,” he confirms.

“We waited for the right machine to come along and the new Tx300P-1800 has fitted in to our print room perfectly,” concludes Spark.